Welcome to the Air and Biomass Catalysis Group of Tianjin university.The research group on atmospheric environment and biomass was established in June 2014 by professor Liu Qingling from the college of environment, Tianjin University.Now we have set up a vigorous young innovation research team composed of 4 professor, 2 associate professors,1 lecturers and many postgraduates.

The research group warmly welcomes undergraduate and graduate students who are interested in air pollution control, environmental nanocatalytic materials, biomass energy and sludge resource utilization, etc. to apply for the master's or doctor's degree in our group.

The main research direction of the research group is:

1. Air pollution and control.

2. Biomass resource utilization.

3. Sludge treatment and disposal technology.

4. Soil remediation and treatment technology.

1. 1. Air pollution and control.

(1)End-treatment technology of volatile organic compounds (VOCs)

VOCs emitted in industrial production have the characteristics of large air volume, low concentration, complex composition, and are not conducive to direct combustion. Currently effective treatment methods are zeolite runner +regenerative thermal oxidizer (RTO) or zeolite runner + regenerative catalytic oxidation (RCO). The focus of our research is the preparation of zeolite materials or adsorbent materials in zeolite runners, and the development of new inexpensive catalysts for low-temperature catalytic oxidation of VOCs.

a. Research and development of adsorbents for VOCs adsorption technology

our research group is currently committed to the preparation and research and development of adsorbents with strong VOCs adsorption capacity and excellent hydrophobic properties, mainly including porous materials such as molecular sieves, metal organic framework materials, resins.

b. Research and development of adsorbents for VOCs adsorption technology

VOCs treated catalysts are mainly precious metal catalysts. Although their treatment effects are excellent, precious metals are scarce and expensive, which are not suitable for long-term sustainable application. Therefore, our research group mainly studies non-precious metal catalysts (mainly transition metal elements) for low-temperature catalytic oxidation of VOCs. It further studies the structure-activity relationship between catalysts and VOCs, and develops a series of efficient catalysts for catalytic oxidation of VOCs.

(2)Research and development of key technologies for denitration based on ship exhaust treatment, industrial exhaust treatment and diesel exhaust aftertreatment.

Using NH3-SCR selective catalytic redox denitration technology, according to the different characteristics and actual differences of mobile source ship exhaust treatment, industrial fixed source exhaust treatment and diesel vehicle exhaust aftertreatment, develop corresponding new material denitration catalysts and more efficient processing system.

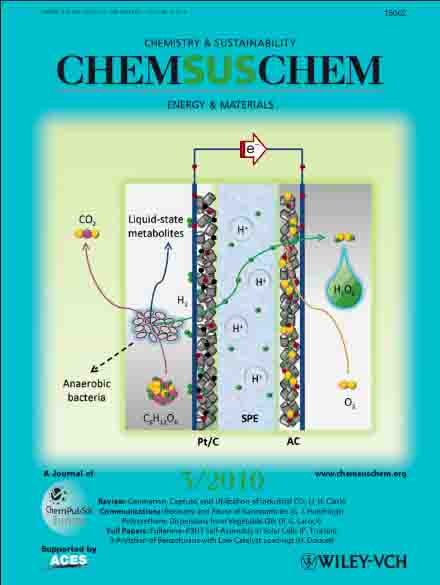

(3)CO2 capture, separation and utilization

The research project of our team mainly takes "artificial carbon cycle" as the main line to carry out the work of efficient CO2 separation, CO2 microbial transformation and CO2 resource reuse.

The main research directions include novel "cryogenic-membrane coupling" CO2 separation technology, the fixation and transformation of CO2 technology by microalgae linked by bicarbonate and the optimization and enhancement of CO2 capture and transformation coupling technology.

a. CO2 separation technology

b. Microalgae CO2 fixation and transformation

c. Process optimization and strengthening

Based on the "calcium looping technology", this research group carries out the work of CO2 capture, CO2 utilization and thermal energy storage. The main research interests include post-combustion CO2 capture based on calcium-based absorbents for industrial sources, CO2 capture coupled CO2 dry reforming to syngas, and high-temperature solar thermochemistry storage.

2. Biomass resource utilization

(1)Biomass catalytic conversion technology

Energy is the basis for the survival and development of today's society. It is also an important indicator for measuring the overall national strength and people's living standards. Among the many renewable energy sources, biomass is the richest, cheapest and sustainable energy source on the planet recycled resources.

In recent years, lignin conversion technologies have been reported, including pyrolysis, high-temperature gasification, liquefaction, supercritical conversion, and biological conversion. And other disadvantages, so research and development of a fast, efficient, green lignin conversion method has attracted widespread attention from scholars.

Lignin is the most complex of the three components of biomass. It consists of multiple units with different benzene ring structures connected by C-C bonds and C-O bonds to form an intricate three-dimensional polymer compound.

Lignin is the most complex of the three components of biomass. It consists of multiple units with different benzene ring structures connected by C-C bonds and C-O bonds to form an intricate three-dimensional polymer compound.

(2)Organic waste energy utilization technology, agricultural waste preparation platform compounds

The main components of lignin biomass include cellulose, hemicellulose, and lignin. Among them, cellulose accounts for the largest proportion, accounting for 38% to 50% of the total biomass. Lignin is the second largest component of biomass resources. It is a natural polymer compound composed of many aromatic benzene ring compounds with different structures linked by different CO and CC bonds. In order to develop high energy with aromatic ring structure, Density oils and chemicals provide the only source of renewable resources. Therefore, studying the conversion technology of woody biomass is of great significance to the development and utilization of biomass resources.

3. Sludge treatment and disposal technology

(1)sludge reduction and resource utilization technology

a. Nanocomposite adsorbents were prepared for water plant sludge

In this study, sludge from drinking water plants can be used as a raw material. The Fe and Al contained in the sludge and the remainder were separated. The magnetic sludge-based nano-iron-aluminum composites obtained by different methods can be used for the removal of F and As (V) in water, respectively. This research not only provides a new way for the recycling of sludge, but also a new method for fluoride removal from drinking water. Accordingly, it can make full use of solid waste to treat contaminated water.

This study investigated the effect of polyaluminum chloride on the acid production of sludge anaerobic fermentation. The potential mechanism of polyaluminum chloride affecting acid production was discussed from the aspects of organic matter dissolution process and sludge floc structure change. Achieve efficient resource utilization of sludge and provide a new direction for sludge resource treatment and disposal.

c. The sludge of plateau municipal sewage plant reduces the amount of dissolved cells and increases the carbon by reflux

c. The sludge of plateau municipal sewage plant reduces the amount of dissolved cells and increases the carbon by refluxThe residual sludge contains a large amount of resource substances, and how to realize the carbon-increasing is the focus of this study. In this study, the effect of different methods on the lysis of residual sludge was studied by using the characteristics and advantages of the sludge from the sewage plant in Lhasa as the research object, and the process of ultrasonic and NaOH + A2O was used to increase the carbon content of the treated sludge. The effect of ultrasonic + NaOH + A2O combined process on the sewage treatment was analyzed, and the sludge reduction effect of the combined process of ultrasonic + NaOH + A2O was evaluated.

(2)Technology and equipment of sludge electrical dehydration and heavy metal electroosmotic leaching

A large amount of sludge is produced in the urban sewage treatment process, and its water content is as high as 95%-99.5%. Ordinary mechanical dewatering cannot meet the requirements for subsequent sludge disposal. In response to this problem, the filterless electroosmosis dehydration was used to further reduce the water content to less than 60% to reduce the sludge volume as well as the thermal energy consumption of subsequent sludge drying and incineration. A simple, reliable and economical fixed electrode push electric dewatering equipment was developed. At the same time, on the basis of this, the electroosmotic leaching technology was proposed to leach and remove the heavy metal in the sludge. The fixed electrode push electric electric leaching equipment was developed to realize various functions of acid injection, leaching and dehydration.

4. Soil restoration and improvement

(1)Soil compounding and improvement techniques

With the situation of population growing, global desertification and cultivated land decreasing, it is of great significance to use means to repair the soil. Sludge, straw, biogas residue and other biomass are focused on, mixed them with fly ash, construction waste, sandy soil and raw soil, then through harmless treatment, fermentation stability, elemental conditioning and mechanical agglomeration, the artificial soil can be manufactured or compounded. It can be used for soil improvement of garden and biomass energy planting as well as surface soil replacement, etc., and waste utilization is realized at the same time.

(2)Contaminated soil remediation technology

Comparing the differences between soil purification, water treatment and gas purification, aiming at the problem of poor fluidity of pollutants in solid media, this paper puts forward the idea of using the electrokinetic principle of low-voltage electric field to improve the fluidity of pollutants in soil, and completes the capture and recovery combined with new functional materials. The technology can be extended to the recovery of heavy metals from tailings.

Tel: 022-8740-1255

E-mail: liuql@tju.edu.cn

Biography: Graduated in 2008 in Dalian University of Technology with PhD degree, 2008-2010 worked as a Postdoctoral Researcher Fellow...